Shoulder Innovations Products

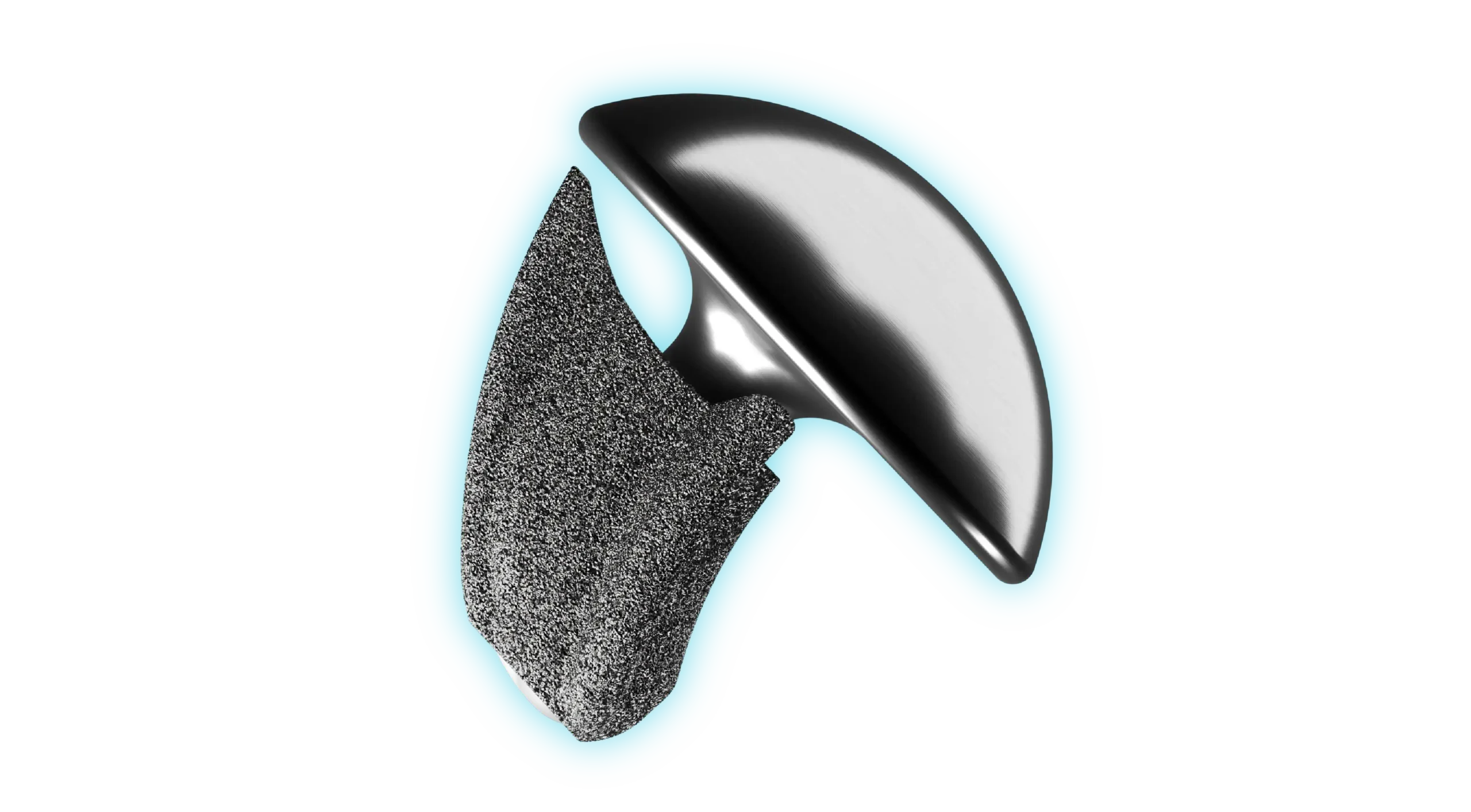

InSet™ Stemless Shoulder System

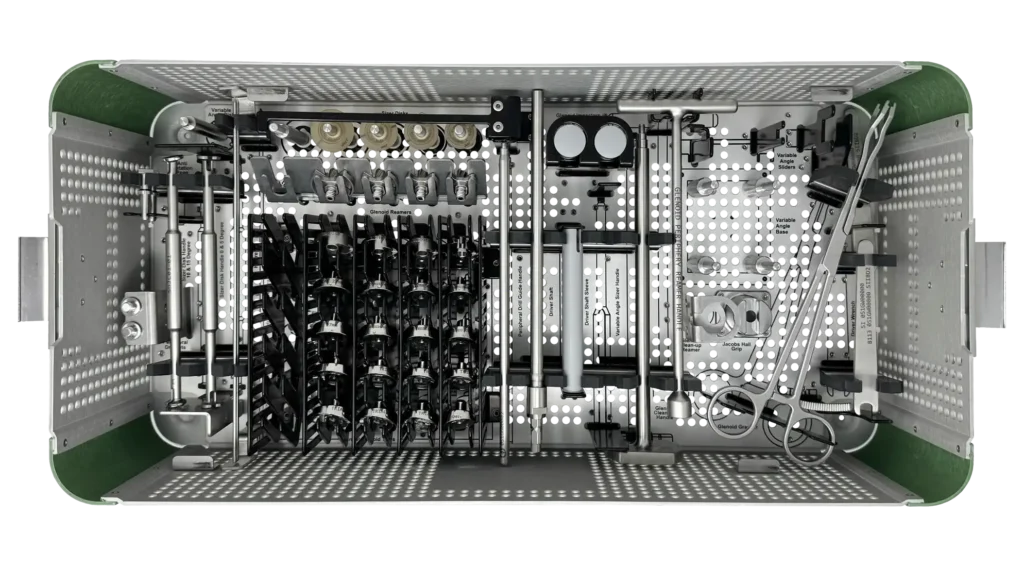

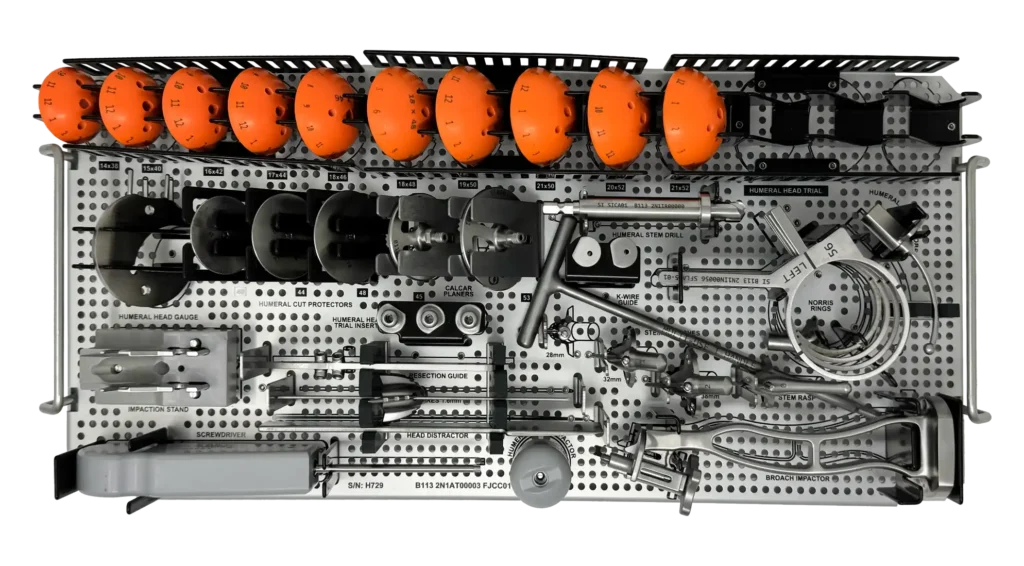

Complete System Integration in a Singular Sterilization Container

The InSet™ Stemless Shoulder System is engineered to provide surgeons with the highest level of intra-operative implant flexibility and efficiency to best serve their patients’ needs.

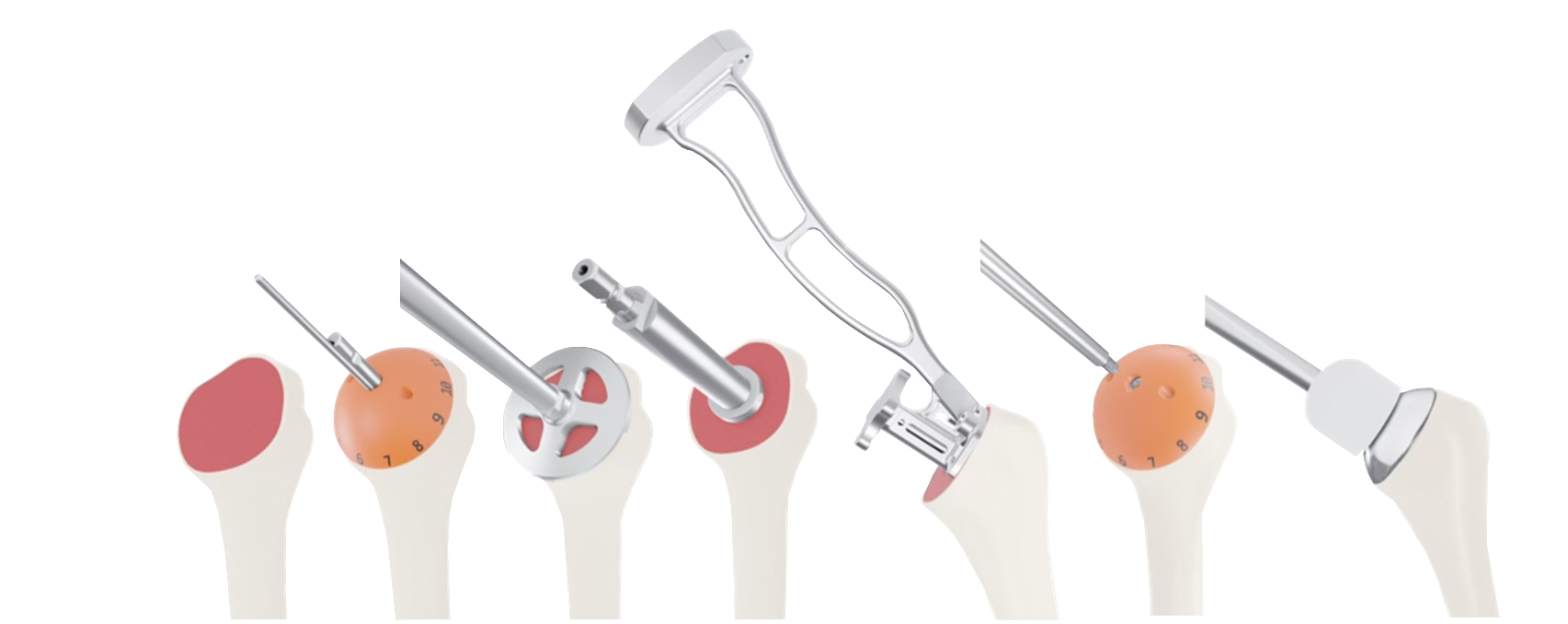

One simplified and reproducible surgical technique allows for the transition from stemless to short stemmed anatomic shoulder arthroplasty at any point in the procedure. The complete set of anatomic instrumentation is contained within one sterilization container for intra-operative efficiency while reducing the instrumentation footprint, surgical time, operating room turn over, and instrument sterilization costs while increasing existing sterilization and processing machinery longevity1.

System Overview

Anatomic Adaptability

Can restore the anatomic center of rotation for more natural biomechanics and kinematics.

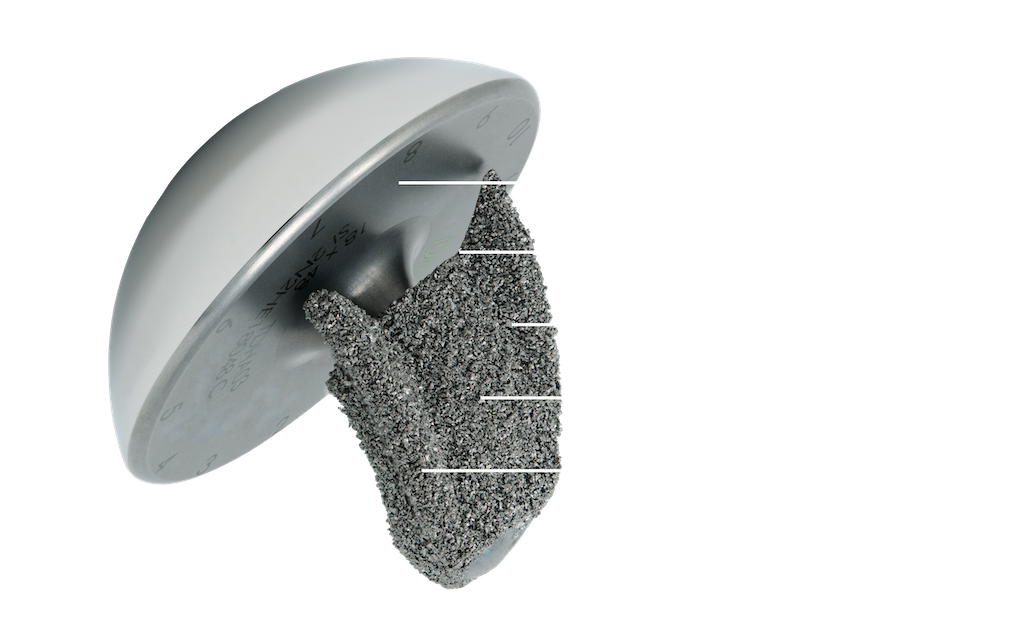

Tested: No-compromise Fixation

Axial pullout strength tested 23% greater and torque-out strength tested 21% greater than a leading linear finned stemless implant2

Curved Fins

Anterior and posterior curved fins contribute to rotational stability that may increase implant survivorship and reduce humeral stress-shielding.

Patented K-Coat Porous Coating

A porous coating process that adds multiple layers of asymmetrical titanium particles using a high temperature sintering process to create a rough, porous surface for initial fixation, while promoting bone growth into the device for long-term stability3.

Collar-less Design

The collarless design allows for cortical rim loading that resists potential implant subsidence and promotes desirable bony adaptations4.

Intra-operative Efficiency and Versatility

One sterilization tray contains all the instrumentation needed for implantation of a stemless or short stem component and an InSet standard or augmented polyethylene glenoid component.

- Reduces operating room instrument footprint.

- Reduces operating room turn-over times.

- Reduces sterilization costs.

- Reduces the potential for tray contamination delays.

References

- Lonner JH, Goh GS, Sommer K, Niggeman G, Levicoff EA, Vernace JV, Good RP. Minimizing Surgical Instrument Burden Increases Operating Room Efficiency and Reduces Perioperative Costs in Total Joint Arthroplasty. J Arthroplasty. 2021 Jun;36(6):1857-1863. doi: 10.1016/j.arth.2021.01.041. Epub 2021 Jan 21. PMID: 33579631.

- Internal data available upon request.

- https://www.avalign.com/porous-coatings-surgical-instruments.php

- Quental, Carlos & Folgado, Joao & Comenda, Manuel & Monteiro, Jacinto & Sarmento, Marco. (2020). Primary stability analysis of stemless shoulder implants. Medical Engineering & Physics. 81. 10.1016/j.medengphy.2020.04.009.

- Liu EY, Kord D, Horner NS, Leroux T, Alolabi B, Khan M. Stemless anatomic total shoulder arthroplasty: a systematic review and meta-analysis. J Shoulder Elbow Surg. 2020 Sep;29(9):1928-1937. doi: 10.1016/j.jse.2019.12.022. Epub 2020 Mar 24. PMID: 32220527.