BONEZONE recently talked with Shoulder Innovations CCO David Blue and other orthopedic leaders to learn what’s driving growth in the shoulder replacement sector and how technologies will likely shape shoulder replacement implants over the coming years.

The following was originally published by BONEZONE. Click here to read the full article.

Streamlining Implants and Instruments

“We love being change agents in this innovative space,” Blue said, “and focusing on solving the real problems that need to be addressed.”

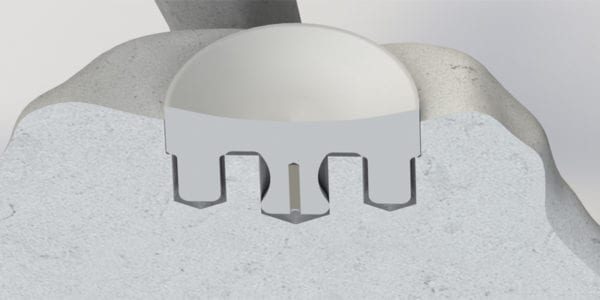

Blue remarked that his company has gained significant acclaim and momentum due to its initial invention of the InSet technology, a stabilization glenoid system that addresses the “rocking horse effect” in shoulder implant recipients. The rocking horse effect occurs when the humerus both rotates and translates on the scapula as it articulates.

“Because we developed a solid solution for addressing glenoid loosening, we’ve taken that product and expanded it even further. We have so much innovative design embedded into that glenoid. It has straightforward instrumentation that makes it special, including not having to worry about radius of curvature mismatch,” Blue said. “We used to have to worry about what size glenoid went with what size humeral head. Now, it doesn’t matter what size head you use with what size glenoid. You can now put the largest head on the smallest glenoid or the smallest head on the largest glenoid. This creates unique flexibility that is recognized and appreciated by surgeons.”

Blue highlighted another significant Shoulder Innovations benefit for surgeons: consolidation and streamlining of implants and accompanying instruments. Rather than requiring large quantities of complex instruments and implants to perform the shoulder replacement surgery, surgeons and hospital staff who work with Shoulder Innovations can expect the same widespread offering and results from only one neatly organized container.

“Being able to build a complete shoulder system from the ground up has allowed us to provide everything into a completely integrated system,” he said. “We call it ‘the value and power of one,’ where you can provide one set of instruments that can work with all our various product options. Because the cost of sterilization labor, wrapping and prepping of the instrument trays and getting them ready for preoperative surgery is about $150 to $250 per tray, depending on where you are in the country. If other companies bring in five or six trays compared to our one tray, we’re providing a huge cost saving to the healthcare facility.”